Efficiency

Efficiency Fans aren’t very effective at ventilating without moving propellers, but what is the best option for your application? At Eldridge, we prefer to use direct drive fans for most general ventilation applications based on selling thousands of fans in our 73 years of existence. In this article, I will compare direct and belt drive fans based on lessons learned from experiences of our customers.

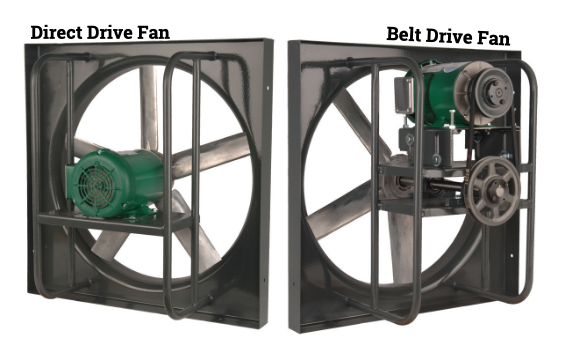

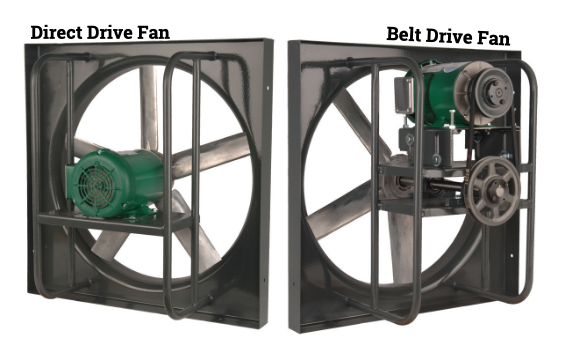

The images of the Eldridge Panel Fans, below, show the difference between a direct drive and a belt drive fan. On a direct drive fan, as implied by the name, the fan propeller is connected directly to the shaft of the motor. Where, on a belt drive fan, the fan motor shaft has a pulley connected by a belt to a second pulley. The second pulley is connected to a shaft that drives the fan propeller.

Efficiency

Efficiency Direct drive fans have no power transmission loss since the propeller is directly connected to the motor shaft. However, a belt drive fan has power transmission loss due to the friction between the belt and sheaves and due to the drive shaft bearings. Even when belts are properly tensioned and the sheaves are aligned, the power transmission loss of a belt drive fan is in the range of 2% to 5% depending on the size of the motor. Winner: Direct Drive

When general ventilation fans are installed within reach of people, they must have guards to prevent contact with moving parts. Although there are more moving parts on a belt drive fan, Eldridge Fans use the same guards for direct and belt drive fans. Winner: Both

Direct drive fans are a “set it and forget it” piece of equipment for maintenance purposes. We have some customers with direct drive fans running for over 15 years without ever needing to perform any maintenance. In contrast, a belt drive fan will require its first maintenance visit within weeks of start-up. With use the belt stretches resulting in lower air flow from your new fan. Over its life span, a belt drive fan will require periodic maintenance to lube drive shaft bearings, align the sheaves and tighten the belt. Winner: Direct Drive

The old school of thought to prevent motor failure was that it needed to be kept out of the airstream. With the wide acceptance of TEFC motors, direct drive fans can be used in all but the harshest environments. Most general ventilation fans are located inside the building where the air is the hottest and heat is the enemy of rubber belts. Winner: Direct Drive

When noise is a factor in fan selection, the sound level of a fan is best reduced by slowing the propeller speed. The propeller speed of a direct dive fan is limited to the standard motor speeds. With a belt drive fan, the size of the sheaves can be adjusted to provide a wide range of slower propeller speeds while utilizing the cheapest motor, a 1750 rpm motor. Winner: Belt Drive

For fan sizes below 42”, a direct drive fan can be configured to cost the same or less than a belt drive fan for most combinations of airflow and static pressure. When airflow specifications require a fan greater than 42” in diameter, a belt direct fan may have an advantage due to motor costs. In these larger fans, the propeller tip speed will dictate using a shaft speed of less than 1750 rpm. For motors with horsepower of 5 or greater, motor costs could be two to three times more than the cost of a 1750 rpm motor, depending upon size. Cost advantages are seen when a large belt drive fan can use the less expensive 1750 rpm motor and reduce the drive shaft speed using sheaves. Winner: Both

Direct drive fans are the overall winner due to low maintenance and greater reliability based on our customer’s experience. Very few customers have the budget for a dedicated maintenance team to perform the required maintenance demanded by belt drive fans. This is why we see so many poorly working belt drive fans when we tour their facilities. We have had a lot of customers ask us to replace their belt drive fans with direct drive fans. We have never had the opposite.